Customized packaging is becoming a remarkable part of the industry. As time passes by brown packaging is replaced by colorful attractive boxes. Custom cbd boxes are more appealing to the customers. They have more features, more sizes, and have innovative look to your product’s packaging.

Also offers protection to every kind of product. If you are using high technology printing, graphics, and other networks then your packaging would stand out among all the competitors. When it will be done nicely and correctly, it will increase the brand exposure and pump up the sales.

Steps:

1.Selection of a suitable material:

A suitable material is a basic step to creating a Custom Cardboard Box. The main material for the shipping boxes is cardboard. We prefer cardboard because of its sturdiness as it is made from wood pulp. For the super support to your products and prevention from pressure and moisture. For more durability, we can convert the card boxes into corrugated sheets. We prefer to use this because of its thickness and the strength they hold. Custom Cardboard Boxes that are made up of corrugated sheets are more in preference because they offer the ultimate protection.

2. Selection for the designer:

Flourishing packaging starts with appealing designs. You have worked with the material now it’s time to choose the designer and have to choose the design for the custom printed boxes. This work should be done professionally. The one who is doing this part should be good with the different fonts, different graphics, and color scheme. Because all of these elements matter a lot and have a significant role in determining efficient packaging. Also take care of things like cutting dies, printing plates, and flute size.

3.Finalization of the dimension.

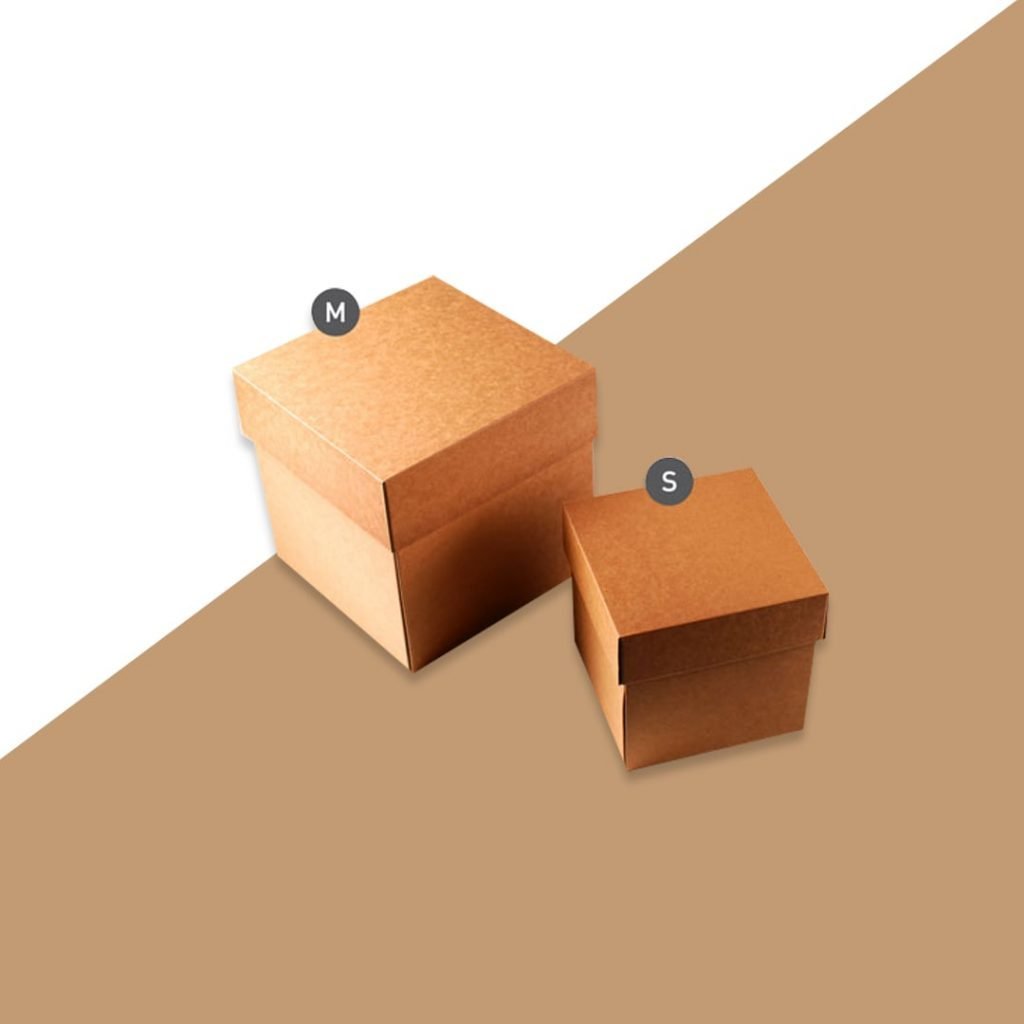

The main step in designing the boxes is work on the dimensions. It’s like which type of box you need. If you need to make the perfect fitted box then you should know about the width, length and height of the product. Also it is suggested that you need to keep a margin of the half of one inch so product can easily fit without tearing the box.

4.Some printing and customization ideas.

Printing is the entire look of the packaging. You can enhance the look of your packaging because of varieties of printing options. The other beautiful patterns, lines, LOGO, and graphics would be so appealing to the customers. The related information like the shade of the product, how to use it can actually be eye-catching for the customers. You can also use customized stickers and fillers. This can be cost-effective as well.

5. Insert fillers

This is probably the last step of the packaging. In this step, we would like to introduce the fillers inside the box to have some protection and for the extra points.

The fillers would be bubble wrap, support cushions for the fragile stuff. It gives the best impression to the client and experiences the great package opening. Add the filler according to the product and own your customized printed box is all ready to be shipped.